Medical Industry

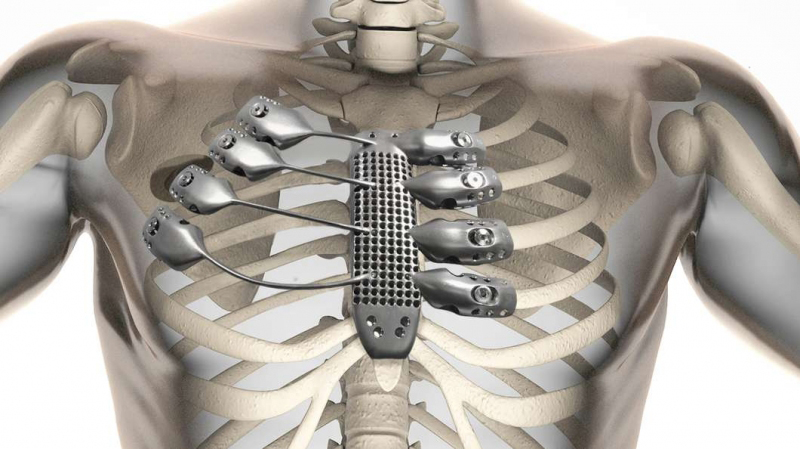

CAD & reverse engineering is increasingly used in the Medical Devices industry.

Firstly, defining a design in the conceptualizing process: getting a visual preview of our concept allows to clarify one's ideas and facilitates.

Then, CAD is relevant when a multi-part assembly must be achieved, whether it be for a customized machine, a device with accessories (as a surgical kit in a sealed blister pack), or multi-component-device; for example when you have to design a port-a-cath used for chemotherapy treatment, which is composed of plastic injected parts, a stainless steel tank and a silicone septum.

The three-dimension representation gives us the possibility to anticipate possible problems and avoid cost increase and project delay. The data reliability of 2D scheme is significantly improved when the 2D plan is created from the three-dimension representation. Mistakes are limited and project planning is optimized.

CAD is also pertinent for marketing purposes. Technological progress now enables to obtain realistic visual displays directly usable in marketing brochures, catalogues or on websites. It is then no longer necessary to wait for the actual physical product to start communicating about it. Time gains can range from several weeks to months.

Finally, three-dimension animation can be performed thanks to CAD. In this case, the main goal is usually to simulate device movements in order to have a better understanding of some component behaviors or to present a concept during exhibitions. For example, we created, in partnership with hospital complex of Lens, a three-dimension animation to provide an innovative medical device which can treat pulmonary tumours.