Rapid Prototyping

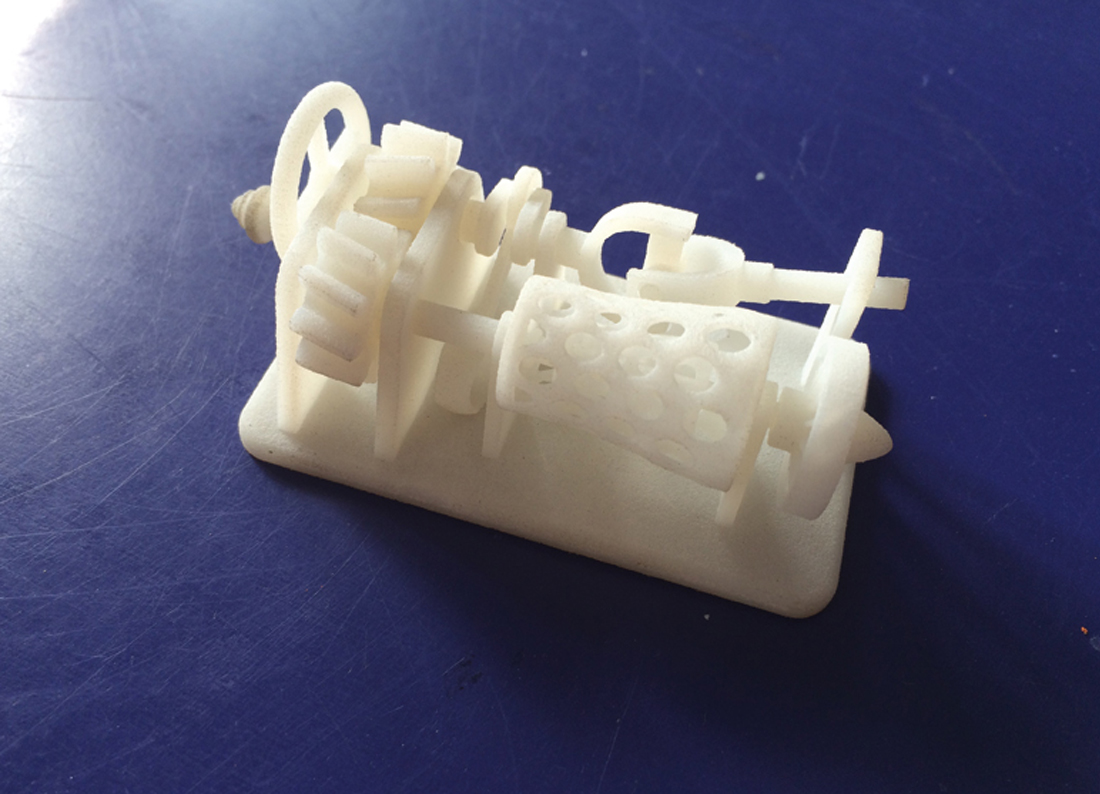

Rapid prototyping is a group of techniques used to quickly fabricate a scale model of a physical part or assembly using three-dimensional computer aided design (CAD) data.Construction of the part or assembly is usually done using 3D printing or "additive layer manufacturing" technology

SLA - SLA is an acronym that stands for StereoLithography Apparatus Stereolithography is the heart of rapid prototyping service, turning your 3D CAD drawing into a solid object.

Fused Deposition Modeling (FDM) is an additive manufacturing technology commonly used for modeling, prototyping, and production applications for bigger application with bigger tolerence (loose tolerance).

SLS - Selective Laser Sintering (SLS) is a process by which machine creates 3D SLS prototypes by fusing or sintering powdered thermoplastic materials or metals to form.

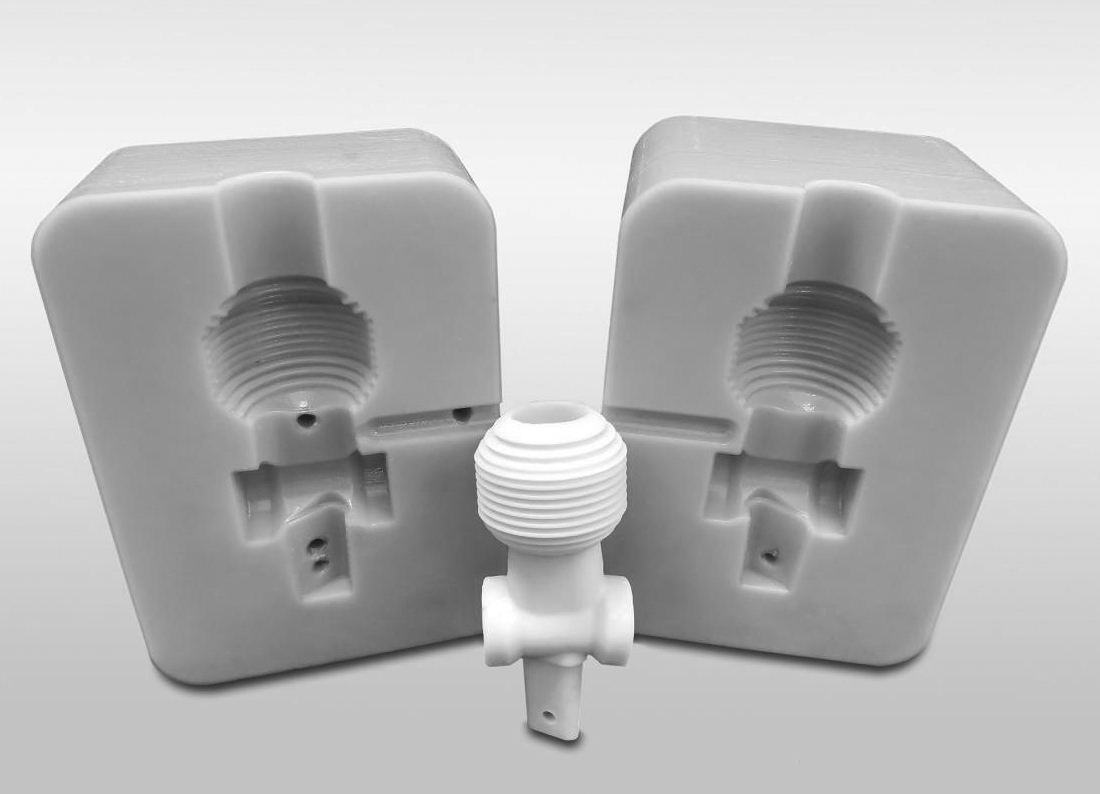

Soft Tooling - Room Temperature Vulcanization (RTV) rubber molds are the fastest, most accurate, and least expensive way to create up to a dozen or so duplicates of a prototype part. Rubber molds can faithfully duplicate details and textures present on the original part, and can be very forgiving of part geometry when it comes time to remove it from the mold. After the RTV Molds are completed, they are then typically used to produce limited quantity polyurethane castings with a wide variety of material properties.

DMLS - Selective laser melting (SLM) or Direct metal laser sintering (DMLS) is a particularly rapid prototyping, 3D printing, or Additive Manufacturing (AM) technique designed to use a high power-density laser to melt and fuse metallic powders together.